Industrial electrostatic powder coating plant for storage rack

- Model

- COLO-L

Item specifics

- Condition

- New

- Type

- Powder Coating Production Line

- Substrate

- Iron

- Coating

- Powder Coating

- Voltage

- As required

- Power(W)

- As required

- Dimension(L*W*H)

- As required

- Weight

- As required

- Certification

- CE

- Warranty

- 1 year

Review

Description

Industrial electrostatic powder coating plant

Powder Coating Object: pallet rack upright & beam, structural I beams

a) Items: L408"*W5"*H60",35000pcs/year

- Items: L 288"*W8"*H 12",3000pcs/year

- Powder Coating Method: Automatic Powder Coating + Manual;

- Curing Oven: Nature gas Type Heating,

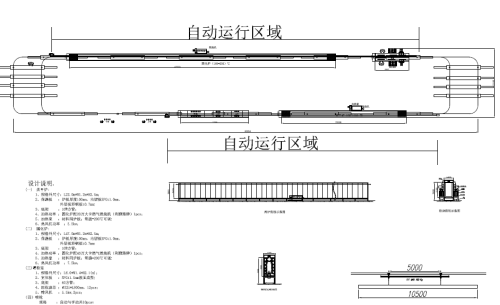

- Workshop Area: 85000×36000×5400mm(L×W×H)

5. warehouse column spacing is 12.19 m to 12.19 m

6.Work Programme:12 hour/shift,270working day/year

2. Production Procedure:

Transport --Work Piece Loading --degreasing phosphating -Rinse1 ---Rinse 2----dehydration oven (80-110℃)→ Automatic + Manual Powder Coating--Leveling--- → Powder Curing (16--20 minutes, 180~220℃) → coolin----Unloading

3.Using unit powder condition

Power--380V/50HZ/3H,heating energy: 8500kacl/m3,industrial water: >=1.5kg/cm2

compressed air : Input pressure:6~8 Bar,oil content less than:0.1ppm,Water content less than:1.3 gm/m3

4. Powder Coating Plant Components (see supplied DWG)

1.Spraying tunnel 1 set

2 .Powder Coating drying Tunnel 1 Set

3.Curing Tunnel Burner (gas ) and Heat Circulation System 1 Set

4.Spraying Booth with recyclone system 1 Set

5..COLO-161S Manual Electrostatic Powder Coating Guns with Control 2 Sets

.Auto Electrostatic Spray Guns with Control 10Sets

6. COLO-2000D Reciprocators, 2 Sets

7. monorail Conveyor system 1 Set

8. Electronic Control System 1 Set

Industrial electrostatic powder coating plant

Powder Coating Object: pallet rack upright & beam, structural I beams

a) Items: L408"*W5"*H60",35000pcs/year

- Items: L 288"*W8"*H 12",3000pcs/year

- Powder Coating Method: Automatic Powder Coating + Manual;

- Curing Oven: Nature gas Type Heating,

- Workshop Area: 85000×36000×5400mm(L×W×H)

5. warehouse column spacing is 12.19 m to 12.19 m

6.Work Programme:12 hour/shift,270working day/year

2. Production Procedure:

Transport --Work Piece Loading --degreasing phosphating -Rinse1 ---Rinse 2----dehydration oven (80-110℃)→ Automatic + Manual Powder Coating--Leveling--- → Powder Curing (16--20 minutes, 180~220℃) → coolin----Unloading

3.Using unit powder condition

Power--380V/50HZ/3H,heating energy: 8500kacl/m3,industrial water: >=1.5kg/cm2

compressed air : Input pressure:6~8 Bar,oil content less than:0.1ppm,Water content less than:1.3 gm/m3

4. Powder Coating Plant Components (see supplied DWG)

1.Spraying tunnel 1 set

2 .Powder Coating drying Tunnel 1 Set

3.Curing Tunnel Burner (gas ) and Heat Circulation System 1 Set

4.Spraying Booth with recyclone system 1 Set

5..COLO-161S Manual Electrostatic Powder Coating Guns with Control 2 Sets

.Auto Electrostatic Spray Guns with Control 10Sets

6. COLO-2000D Reciprocators, 2 Sets

7. monorail Conveyor system 1 Set

8. Electronic Control System 1 Set

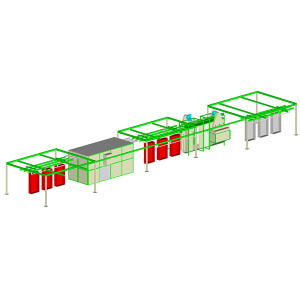

Powder coating line includes:

1. Pre-treatment system : Automatical Spraying pre-treatment and dipping pre-treatment are available;

2. Drying oven : Drying oven which drying the water after pre-treatment is designed according to

custmoer actual conditions.

3. Powder coating spray system: Auotmatic spray reciprocator, Maunal spray equipment and Semi-

auto (Auto-spraying with manual reparing spraying) are for your choice;

4. Powder recycling system: Cyclone equipment and cartritdge filters is customized and introduced

according to actual requirement by customer;

5. Curing oven : Tunnel curing oven, bridge type curing oven, Electric power heating curing oven,

Gas-heating curing oven, Diesel heating curing oven, High temperature, lower temperature curing

oven is available for fitting your sole factory.

6. Conveying system: Various design according to different requirement by customer on the basis of

customers' workpiece and output information.

If you want to custom made any powder coating line,pls tell us the following specifications:

1. The size of workpiece,especially the max size

2. The max weight of the workpiece

3. Is there any requirements about the suspension of the workpiece?

4. The material of the workpiece

5. The anticipative output for the biggest size of the orkpiece(how many pcs in 8 hours)

6. The length,width and height of the factory available for the powder coating line

7. The heating power:Liquefied Petroleum Gas, Liquefied natural gas,diesel,or electric?

8. Do you need to change colors every day? How many colors do you have in total?

9. Do you need automatic painting or manual painting?

10. Do you need pre-treatment process? If you do,you like spray pre-treatment or bath pre-treatment?

11. The local electricity conditions(_V/_Phase/_Hz)

12. Do you have any special requiremnts about the package?

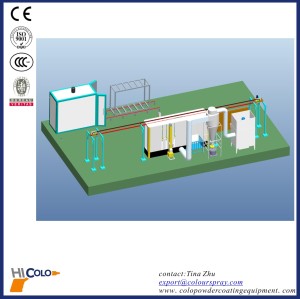

Installation of powder coating application for customer in Russia

Various application of Colo powder coating line

We have specialized engineers to design and manufacture automatic plants with various processes as per customers requirement.This plant consists of several processes which are made into one by our specialized design.

Our services:

We deliver the goods to any ports in China,or deliver to the place as required

can ship within 30 days .

Packing: proper packing suitable for deliver

Services: we supply all equipments about the powder coating, such as booth, oven, reciprocator, gun, line, semi-line and plant and spare parts.

Why choose us:

design

drawing

illustration

commissioning

training

technical support

Quality Control:

testing in any step from material supplier to goods deliver.

Booths and oven size could Custom designed,Manual and automatic spray stations are also available.

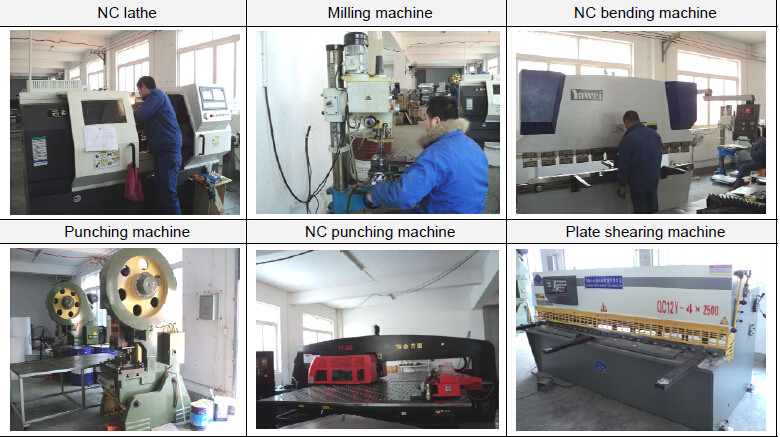

Company Information:

1,products sample

2,machines

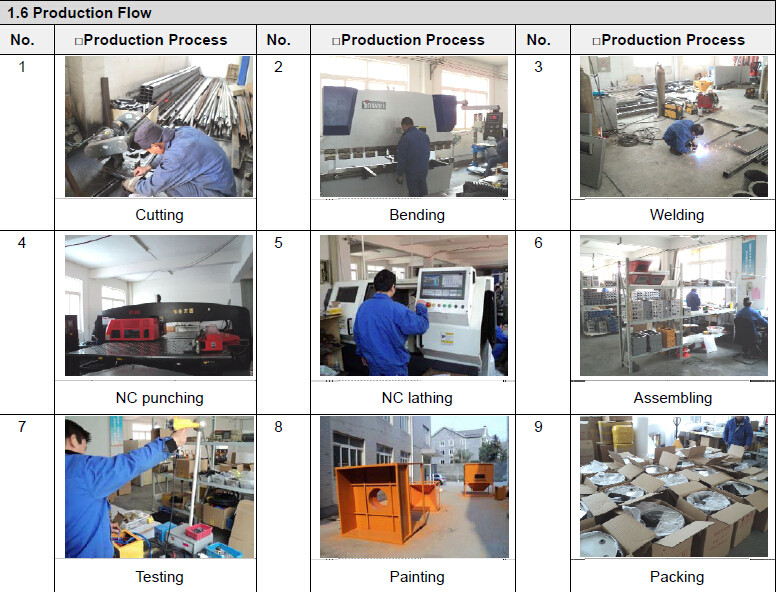

3,production flow:

Customer Visting:

powder coating gun, powder coating machine, powder coating system,powder coating equipment,powder coating control unit

COLO are specialized in complete electrostatic powder coating line, paint coating plants ,curing and drying ovens, cartridge type and cyclone recovery systems, spray booth, conveyor systems, Also we are supplier of powder coating, powder filters, powder coating machine,powder coating equipment,powder coatting gun,,Reciprocator, painting guns, pumps and their equipments.