Box Feed powder painting machine

- Model

- COLO-161S-F, COLO-161S-F

Item specifics

- Condition

- New

- Type

- Manual powder coating machine

- Substrate

- Steel

- Coating

- Powder Coating

- Voltage

- 100-240V

- Power(W)

- 50W

- Dimension(L*W*H)

- 120*80*80CM

- Weight

- 55KGS

- Certification

- CE

- Warranty

- 1 YEAR

- After-sales Service Provided

- Engineers available to service machinery overseas

- electrostatic painting equipment

- Manual powder coating machine

- Model

- Vibrator

- Machine

- Vibrator powder painting spray machine

- Size

- 118x79x50cm

- weight

- 70kgs

- Application

- Paint Spray Gun

- power chane

- with original carton

Review

Description

Box Feed powder painting machine

Box Feed powder painting machine

1,Vibratory Box Feed electrostatic painting equipment

2. good for quick and easy color change

Typical characteristics

manual box unit is good for quick and easy color changes,It is designed to use the powder manufacturer’s original carton. An inclined vibration table allows complete emptying of the powder box via the fluidized suction tube.

1.The frequent replacement of color more convenient

2.Fast color change

3.Can directly use the powder box

4.The vibration of the electric vibrator, the noise reduction, extinction powder powder box

0-100 Digital Adjustable KV

Fully Adjustable Amperage

Interchangeable with the Gema original equipment

Fully Adjustable Air for Pump on Pressure, Dosage and Nozzle Rinsing Air.

Comes with Full Array of Nozzle Assortment.

Field Tested and Proven to operate in the toughest environments.

Comes with different array of delivery systems:

Because this system is specially balanced for the maximum spray capability with

the Smoothest Finish Possible.

Electrical data

Mains input voltage: 220V/110V

Operating frequency: 50Hz /60Hz

Powder: 50W

Output voltage (to the gun): 0-100KV ( adjustable)

Maximum output current (to the gun): 180UA(max)

Protection type: IP54

Approvals: CE Certification

Pneumatical data

Input pressure: Min. 6 bar(87PSI)/max. 10 bar(145PSI)

Recommended input pressure: 7 bar(101.5PSI)

Max. Water vapor content of the compressed

Air 1.3 G/m 3;

Max. Oil vapor content of the compressed air 0.1 mg/m3;

You can direct change the mchine in manual or automatic.

There have the Model for flat parts paiting, for repeat coating and for comliziert parts.

Very easy to use.

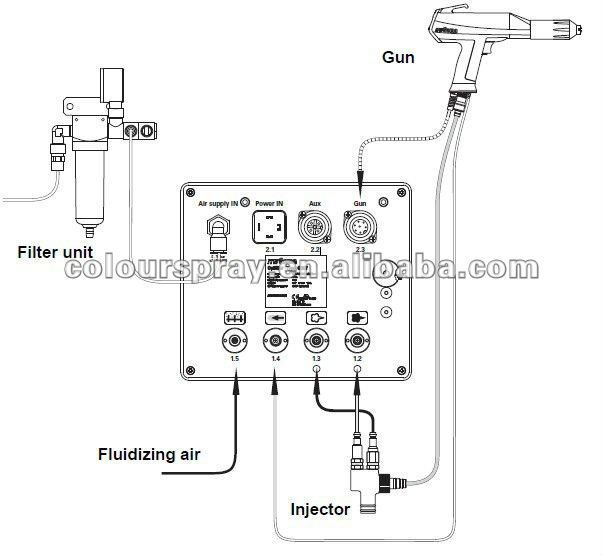

Connection

Packeage:

Powder coating is a type of coating that is applied as a free-flowing, dry powder. The main difference between a conventional liquid paint and a powder coating is that the powder coating does not require a solvent to keep the binder and filler parts in a liquid suspension form. The coating is typically applied electrostatically and is then cured under heat to allow it to flow and form a "skin". The powder may be a thermoplastic or a thermosetpolymer. It is usually used to create a hard finish that is tougher than conventional paint. Powder coating is mainly used for coating of metals, such as "whiteware," aluminium extrusions, and automobile and bicycle parts. Newer technologies allow other materials, such as MDF (medium-density fibreboard), to be powder coated using different methods.

COLO Powder Coating Systems is a top supplier of powder coating systems and powder coating equipment including automated equipment, spray booths and spare parts for famous brand in china.

powder coating gun, powder coating machine, powder coating system,powder coating equipment,powder coating control unit