Electrostatic new compact design powder coating system

- Price

- US $890

- Model

- CL-668-L3

- MOQ

- 1 piece

Item specifics

- Condition

- New

- Type

- Manual powder coating equipment

- Substrate

- Steel

- Application

- Powder Coating

- Voltage

- 110/220V

- Power(W)

- 50W

- Weight

- 35KGS

- Certification

- CE

- Warranty

- 1 YEAR

Review

Description

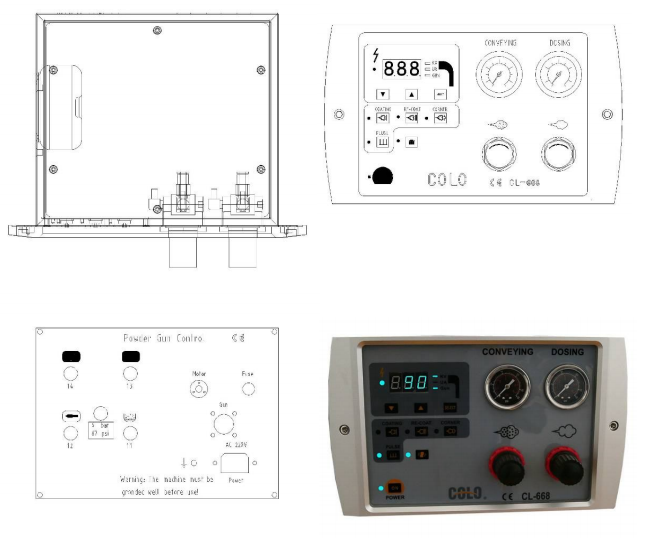

Electrostatic new compact design powder coating system Control unit

It has pulse and one-touch intelligent function, and is good for flat parts, complex parts, recoat parts and conner.

Flat model: maximizes voltage for superior transfer efficiency with coating flats parts.

Complex model: adjust the voltage while holding current when coating complicated shapes and corners.

Recoat model: adjust the voltage and current automatically for recoating of parts.

Pulse model: rapidly recharges the powder to coat complex shapes.

y

y

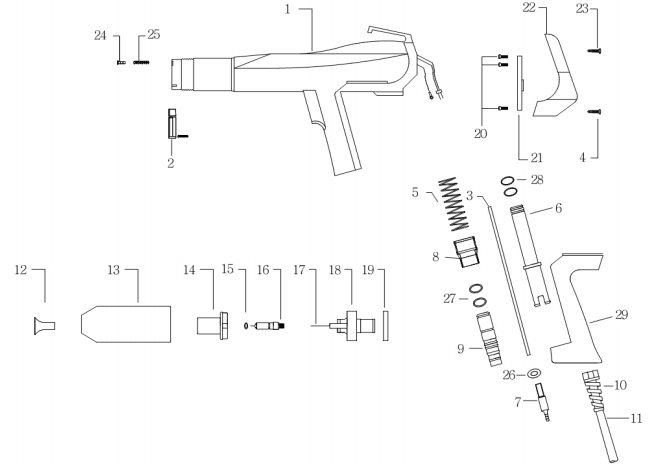

Spare parts of the powder coating application equipment

The powder coating equipment is built exclusively for electrostatic coating with organic powders.

The electrostatic powder manual coating equipment with the COLO-07 manual powder gun is ideally

suited for manual coating of objects in small series.

Spare parts code

| 1007 220 | gun body |

| 1007 231 | cascade,negative plarity |

| 1007 216 | Print holder - complete |

| 1007 217 | End plate with hook |

| 1007 961 | Grip end plate - complete |

| 1007 213 | Trigger - complete |

| 1007 212 | Trigger cover |

| 1000 845 | Countersunk-head screw - M4x6 mm |

| 1007 963 | gun cable 2m-complete |

| 1007 964 | gun cable 6m-complete |

| 1007 965 | gun cable 12m-complete |

| 1000 804 | Rinsing air connection |

| 1007 958 | Powder tube - complete |

| 1001 488 | Compression spring |

| 1007 960 | Clip ring |

| 1000 822 | o-ring |

| 1001 340 # | Hose connection Ø 11-12 mm - complete |

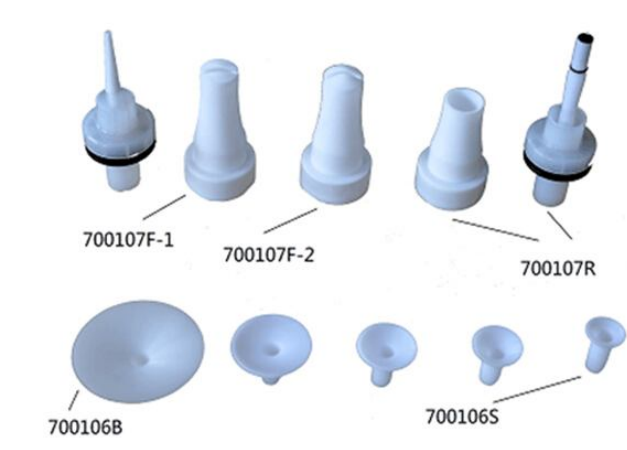

| 345 822 | Ø 50 mm |

| CL1007 683# | Electrode holder |

| CL1007 934# | Flat jet nozzle NF20 |

| CL1007 931# | Flat jet nozzle NF20 - complete |

| CL1007 935# | Flat jet nozzle NF21 |

| CL1007 932# | Flat jet nozzle NF21 - complete |

| CL1008 147# | Flat jet nozzle NF24 |

| CL1008 142# | Flat jet nozzle NF24 - complete |

| CL1008 151 | rounded spray nozzle |

| CL1008 152 | Electrode holder |

| CL1008 150 | GM03 rounded spray nozzles |

| CL1007 735 | NF25 |

| CL1007 742 | NF26 |

| CL1008 257 | NS09 |

| CL1007 684 | |

| CL1008 258 | |

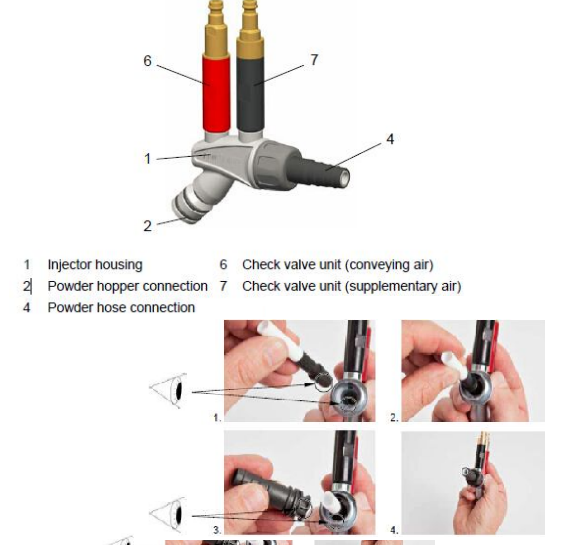

| Powder injector | |

| CL1007 780 | Powder injector (type IG06) |

| CL1006 530 | Injector body |

| CL1006 484 | Injector body(without o-ring) |

| CL1005 589 | only sell in one full set,A.B.C.D |

| CL1005 590 | |

| CL261 654 CL103 500 | |

| CL1008 038 CL261637 | |

| 1003 698 | Filter element - Ø 9/4x27 mm |

| CL1006 485-colo | Teflon |

| CL1006 485-A | Teflon, complete |

| CL1006 485-B | |

| CL1006 531 | Hose connection |

| CL205 141 | o-ring |

| CL1006 483 | Threaded sleeve |

| CL1006 488 | nozzle |

| CL1007 792 | nozzle fixation |

| CL1007 794 | o-ring 16x2 |

| 1007 971 | ,GM03 manual powder gun ,negative polarity ,gun cable 2m |

| 1007 972 | negative polarity, gun cable 6 m |

| 1007 973 | negative polarity, gun cable 12 m |

Power Source | AC220V/110V |

Frequency | 50~60Hz |

Power Consumption | 30W |

Voltage Output | 100kV |

Max. Current Output | 18uA |

Polarity | Negative |

Max. Injection Capacity | 650g(22.9oz.)/Min |

Air Consumption | MAX. 13Nm3/h |

Temperature Rage in use | -10~50℃(-14~22℉) |

Special features

1.Colo Newly integrated technology can lead to powder savings due to excellent transfer efficiency, easily penetrating corners

2.Colo Anti-static powder hose is developed with colo technology and it can prevent risk of fire by removing spark or electrical arc.

3.Prevents safety accidents caused by electrostatic shocks to the worker.

4.The new technology of one touch button installed in the gun enables you to clean inside of the gun and powder hose easily and quickly.

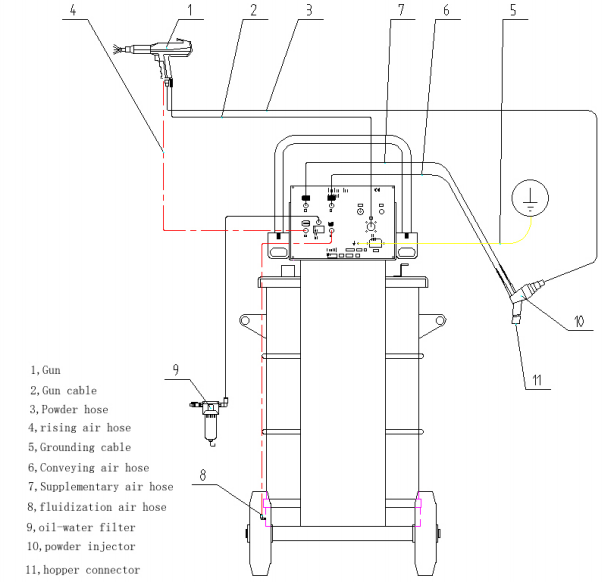

-INSTALLATION

→Propery ground all equipment in the spray area to an earth ground and maintain this ground

→Remove all containers of volatiles from the spray area

→Establish and maintain a grounded area for the spray operator

→The gun of xseries must be connect to xcontrol unit

→OPERATION

→The operator should hold the gun in his bare hand

→If gloves are worm ,the palm should be out to assure skin to metal contact

→The operator should wear shoes with conductive shoes e.g leather

Rubber shoes are not conductive .

→Ground the tip of the gun before cleaning or changing nozzles.

→When the gun is not in use , it should be hung so that the nozzle is within four inches of a grounded conductor

→The operator should wear a filter-type respiator anytime he is exposed to dusty conditions

→High pressure powder many cause injury ,Keep the rear switch “off” position in no –use condiction

MAINTENANCE

→Make a periodic confirmation of grounding to earh of all equipment in the spray area .

→Exercise good housekeeping practices , do not allow dirt or powder to accumulate on the feeder /powder unit , cable or gun.

→Keep the cabinet door

Colo has exported to more than 90 countries, such as Mexico, Colombia, Peru, Canada, the United States,

Brazil, Russia, Poland, France, Germany, Italy,Egypt, Vietnam, India, Saudi Arabia, South Africa and other countries.

We have built good long-term relationship with our customers. They come to visit our factory from time to time.

Colo is the leading powder coating equipment manufacturer in China, which provides high quality equipments

to more than 90 countries all oven the world with advanced manufacturing machines and professional

technicians. Colo offers a wide range of power coating equipments, namely powder coating machine, power

coating gun, spray booth, curing oven, automatic powder coating applicator, powder coating line and

replacement of spare parts for the famous brand in the world.

Welcome guests from all countries in the world to visit our factory.