Intelligent manual spraying painting machine for test and small batch with 500ml cup

- Price

- US $500-900

- Model

- CL-668T-06C

- MOQ

- 1 piece

Item specifics

- Condition

- New

- Type

- Manual powder coating equipment

- Substrate

- Steel

- Coating

- Powder Coating

- Voltage

- 100-240V

- Power(W)

- 50W

- Weight

- 15KGS

- Certification

- CE

- Warranty

- 1 YEAR

Review

Description

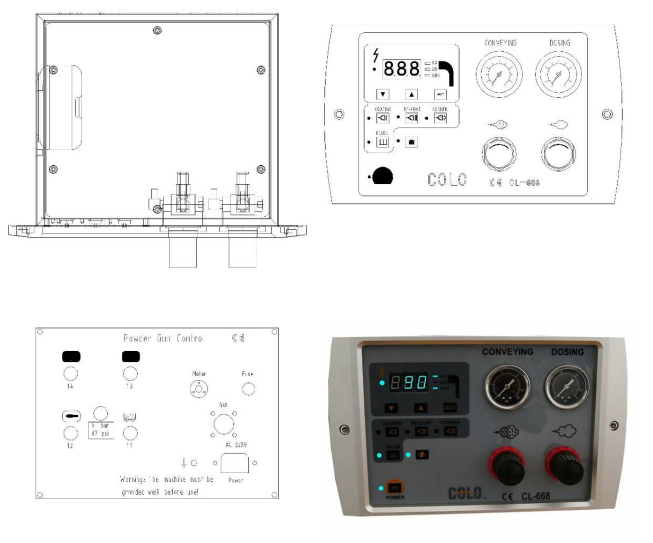

Typical characteristics of Intelligent manual spraying painting machine

- Easy to operate

Enhanced coating quality of flat and complex parts

• Reduced operator fatigue

• Effective coating in corners and recesses

• Improved recoating ability

\

\

Application of Intelligent manual spraying painting machine

The powder spray equipment is built exclusively for electrostatic coating with organic powders.

The electrostatic powder manual coating equipment with the COLO-06 manual powder gun is ideally suited

for manual coating of objects in small series.

Spare parts of COLO-06 manual powder gun-Compatible with Opti

Technical Data

Electrical data

- Power range 220V/110V

- Frequency 50HZ /60HZ

- Temperature range in use -10 ℃+50 ℃

Powder Gun

- Gun weight: ……………… 500G

- Rated output voltage ……… 24VDC

- Input voltage …………… - 200kv

- Maximum output current ……… 180Ua(max)

- Maximum output voltage………… 0-100KV ( adjustable)

- Maximum powder injection :……… 600g/min

- Polarity ……………… negative (-)

Pneumatic data

- Maximum input-air pressure ………….. 10kg/cm

- Optimum input-air pressure…….. 6kg/cm

- Minimum input-air pressure …… 4kg/cm

- Maximum water vapor content or compressed air ….. 1.4g/N m3

- Maximum oil vapor content of compressed air …….. 0.1ppm

- Maximum compressed-air consumption……… 13.2 m3/h

-INSTALLATION

→Propery ground all equipment in the spray area to an earth ground and maintain this ground

→Remove all containers of volatiles from the spray area

→Establish and maintain a grounded area for the spray operator

→The gun of xseries must be connect to xcontrol unit

→OPERATION

→The operator should hold the gun in his bare hand

→If gloves are worm ,the palm should be out to assure skin to metal contact

→The operator should wear shoes with conductive shoes e.g leather

Rubber shoes are not conductive .

→Ground the tip of the gun before cleaning or changing nozzles.

→When the gun is not in use , it should be hung so that the nozzle is within four inches of a grounded conductor

→The operator should wear a filter-type respiator anytime he is exposed to dusty conditions

→High pressure powder many cause injury ,Keep the rear switch “off” position in no –use condiction

MAINTENANCE

→Make a periodic confirmation of grounding to earh of all equipment in the spray area .

→Exercise good housekeeping practices , do not allow dirt or powder to accumulate on the feeder /powder unit , cable or gun.

→Keep the cabinet door

Colo has exported to more than 90 countries, such as Mexico, Colombia, Peru, Canada, the United States, Brazil,

Russia, Poland, France, Germany, Italy,Egypt, Vietnam, India, Saudi Arabia, South Africa and other countries.

We have built good long-term relationship with our customers. They come to visit our factory from time to time.

Colo is the leading powder coating equipment manufacturer in China, which provides high quality equipment to more than 90 countries all oven the world with advanced manufacturing machines and professional technicians. Colo offers a wide range of power coating equipments, namely powder coating machine, power coating gun, spray booth, curing oven, automatic powder coating applicator, powder coating line and replacement of spare parts for the famous brand in the world.

Welcome guests from all countries in the world to visit our factory.

COLO Powder Coating Systems is a top supplier of powder coating systems and powder coating equipment including automated equipment, spray booths and spare parts famous brand in china.