Manual Powder Coating Equipment with 500ml cup

- Price

- US $1

- Model

- colo-660-T-C

- MOQ

- 1 piece

Item specifics

- product attribute

- intelligent machine

- packing

- Carton or wooden cases

- range of application

- testing powder or laboratory

- Voltage

- 220V

- Power(W)

- 50W

- Warranty:

- 1YEAR

- Certification

- CE/ISO

Review

Description

colo-660 intelligent machines in the series is our most popular products .

It has intelligent function and pulse function .Highly recommended by the colo!

This machine is for laboratories and product development departments.

1.Advantages and characteristics:

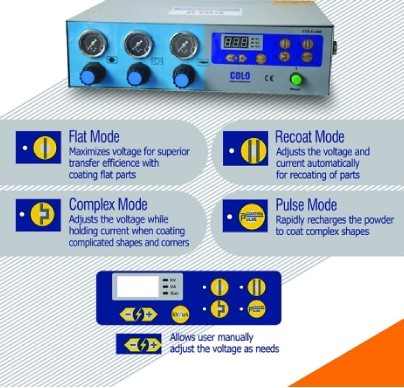

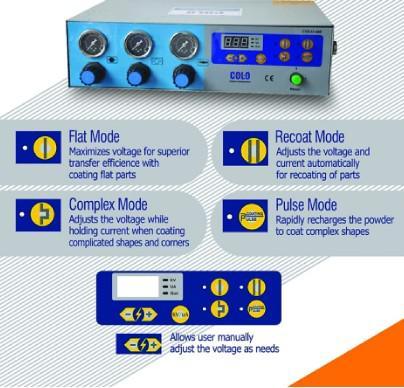

Corners Mode: For spraying complex shapes and corner parts

Again painting modes: easy to be used due to electrostatic repulsion painting or two times when painting

Pulse mode: Order repeatedly charged powder coating applied to complex shapes

Tablet Mode: static electricity to the best senior painting, the play superior performance.

2.→Technical Data

Power range 220v

Frequency 50/60HZ

Temperature range in use -10 ℃+50 ℃

Powder Gun

Gun weight: ……………… 500G

Rated output voltage ……… 24VDC

Input voltage …………… - 200kv

Maximum output current ……… 180Ua(max)

Maximum output voltage………… 0-100KV ( adjustable)

Maximum powder injection :……… 600g/min

Polarity ……………… negative (-)

Pneumatic technical spec

Maximum input-air pressure ………….. 8kg/cm

Optimum input-air pressure…….. 6kg/cm

Minimum input-air pressure …… 4kg/cm

Maximum water vapor content or compressed air ….. 1.4g/N m3

Maximum oil vapor content of compressed air …….. 0.1ppm

Maximum cimpressed-air consumption……… 13.2 m3/h

TPulse coating ………….. ………….. ………….. 15~20 clock/sec

3.Picture presentation:

COLO-660-T-C

cup gun this is for testing job ( cup gun can hold about 129gram )

Packing Dimensions

Length: 44cm

Width: 44cm

Height: 56cm

Weight: 12 kgs.

![]()

Powder coating is a type of coating that is applied as a free-flowing, dry powder. The main difference between a conventional liquid paint and a powder coating is that the powder coating does not require a solvent to keep the binder and filler parts in a liquid suspension form. The coating is typically applied electrostatically and is then cured under heat to allow it to flow and form a "skin". The powder may be a thermoplastic or a thermoset polymer. It is usually used to create a hard finish that is tougher than conventional paint. Powder coating is mainly used for coating of metals, such as "whiteware," aluminium extrusions, and automobile and bicycle parts. Newer technologies allow other materials, such as MDF (medium-density fibreboard), to be powder coated using different methods.