Overhead Chain Conveyor Track for powder coating line

- Model

- COLO-L, COLO-chains

Item specifics

- Condition

- New

- Type

- Coating Production Line

- Substrate

- metallic

- Coating

- Powder Coating

- Voltage

- 380V/220V/110V

- Power(W)

- 50W

- Certification

- CE

- Warranty

- 2 year

- After-sales Service Provided

- Overseas service center available

Review

Description

Colo Overhead Chain Conveyor Track for powder coating line

Advantages

- Longer Chain Life

- Smoother Operation

- Quieter Operation

- Less Downtime

- Greater Reliability

Benefits

- Lower Replacement frequency

- Reduced system drag for increased system life

- More ergonomic, easier on workers

- improved efficiencies

- Cheaper maintenance and lower total system costs.

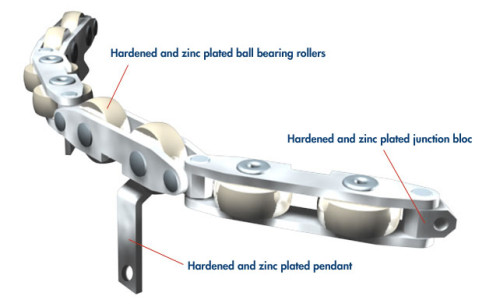

Features of Overhead Chain Conveyor Track for powder coating line

Drive through a geared motor unit to the track chains. pusher dog in the track to throw the chains. then make the chain moving. track type to ensure free and smooth transmission of power. it's quieter.

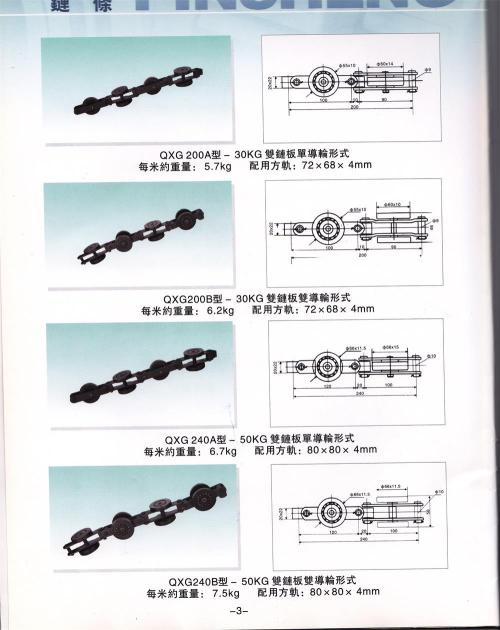

The standard level of weight-bearing type wheel to improve its carrying capacity and wear resistance and prolong its service life, suitable for higher temperatures and more curved or production environment. Suspension spacing: 150 * N (MM), the chain weight per meter 4.58KG, single hanging weight of not more than 40 kg, the chain tension is not greater than the allowable 30KG, chain breaking force of not more than 55KG, use temperature of 300 degrees.

Overhead Chain Conveyor for powder coating

Consists of pretreatment, powder coating, drying oven and curing oven, conveyor system and electric control system.

It will help user expand output, form mass production and reduce cost in order to make products’ price more competitive.

1.Compective price

2.Energy saving

3.Output improve

4.Clean and economical

Hangzhou color powder coating Equipment Co., Ltd. have ability of producing electrostatic powder coating line, paint

coating line which have automatic, semi-automatic, manual and special type and curing and drying ovens with many kinds

heat way (oil, gas or electric),cartridge or cyclone recovery system, wet curtain or dry painting booth, conveyor systems,

spray or immersion type pretreatment plant.Also we supply the spare parts such as filters, guns, reciprocators, pumps and

so on.