Powder injector 1007 780 with coded quick release connections

- Model

- 1007 780

Item specifics

- Used for

- electrostatic powder coating

- how long deliver

- 1-2 days after payment

- MOQ

- 1 piece

- lifetime

- depend on different type powder

- Model

- 1007 780

Review

Description

Powder injector 1007 780 with coded quick release connections

The injector is used to convey normal organic powders between the powder hopper and the powder gun. The injector is

supplied with a PTFE insert sleeve as standard. The plug-in injector allows fast cleaning and easy handling because it can be

detached from the powder hopper without using any tools. All connections are plug-in and not interchangeable (when using in

manual equipment). The injector can be disassembled without special tools.

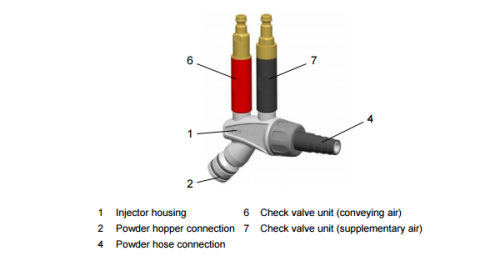

Structure of the powder injector

Principle of the injector

If air flows through the nozzle into the cavity, a vacuum is created in the cavity (see figure below). This vacuum causes powder to

be drawn up the suction tube and into the cavity. A powder/air mixture is created. The forward air velocity at the nozzle conveys

the powder/air mixture through to the powder hose to the gun.

Application of powder injector

Theory of powder coating

The powder goes through the powder hose . The powder is electrostatically charged at the nozzle of the gun.

In addition, an electrostatic field is created between the gun nozzle and the grounded object. The

charged powder spray remains adhered to the surface of the object.

The powder is fluidized by air forced through a porous plastic plate from below. The powder

acquires, thereby, fluid-like characteristics.The conveying air, supplementary air, and rinsing air

are set on the control Unit.