Low consumption Gas Fired Powder Curing Oven

- Price

- US $5000

- Model

- COLO-3518

- MOQ

- 1 piece

Item specifics

- Model No

- COLO-3518

- voltage

- 380V /220(3 phases)

- Powder supply

- Gas

- Categories

- Gas powder coating oven

- Burner

- Italy Riello, 10,0000cal

- Temperature:

- RT+10~250°C

- Temperature max.:

- 250° C

- Warm-up time:

- 15-30 min. (180° C)

Review

Description

Features of Gas Fired Powder Curing Oven

This Powder curing oven is used for curing the workpiece which has been spraying during the powder coating. When a thermoset powder is exposed to elevated temperature, it begins to melt, flows out, and then chemically reacts to form a higher molecular weight polymer in a network-like structure.

- Precise temperature control, furnace tolerance of +/- 5 degrees Celsius. Indirect heating system with a heat exchanger.

- Hot air is transferred from the bottom up.

- Heat exchangers used in seamless steel tubes 8x8 array, use the combustion liner 310S stainless steel

- seamless pipe thickness of 3-4mm.

- Closed-round clean efficient heat circulation system

- Safely and efficiently cure previously applied electrostatic powder coating oven

- Energy-efficient designs save fuel and get to temperature quickly

- Feature premium 100mm thick insulated wall and roof panels

Specifications of Gas Fired Powder Curing Oven

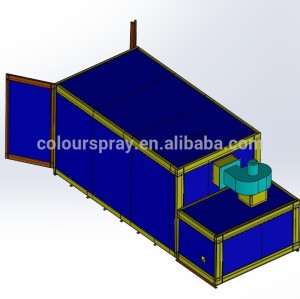

Model | colo-3518 |

Worksize dimensions | 1800 width x 1800 height x 3500 depth |

Overall dimensions | 2100 width x 2100 height x 4840 depth |

Power supply | Gas |

Voltage/Frequency | 380V(50-60hz) |

Warm-up time | 15-30 min. (180° C) |

Temperature stability | < ± 3.0-6°C |

Temperature max. | 250° C |

Burner | Italy Riello, 10,0000cal |

Circulation/ Air flow | Vertical ,Variable through holes on the walls |

Ventilation performance | 1131-2565m3/h |

Motor power | 1.5 kW |

Warranty | 12 months |

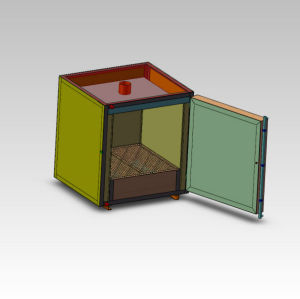

Structure of the Gas fires powder curing oven

It consists of body,insulation, cover, heater, fan motor, track, trolley and PLC system.

1. Thick insulation 100-150mm

Use Gas to create the energy ,through the circulating fan ,make the temperature in the oven to rise uniformly. Then make the temperature of workpiece to rise.

built-in track to roll your powder coating racks into the ovens could be ordered together as you required.

2. The heating exchanger system in the heating room

Keep the inner of the oven clear and could get very good curing effect. The surface of the workpieces

will be very smooth with this type powder coating oven.

- The heat exchanger specification

- The heating room

- Burner-Italy Riello

Italy imported burner can be put in the side or top place.

A gas burner and a fan is required for heating the inside of the CURING OVENS. The curing temperature

depends on the requirement of powder materials. The material is heated by the hot air in the curing oven

which helps in heating the coating. The curing time may be short or long depending upon the load of the

product. Curing Oven is dependable and flexible.

gas burners, completely automatic, with one stage settings fitted with:

- Fan with forward curve blades

- Cover lined with sound-deadening material

- Metallic and fixed air damper with adjustment

- Single phase electric motor 230 V, 50 Hz

- Combustion head fitted with:

- stainless steel head cone, resistant to high temperatures

- ignition electrodes

- ionisation probe

- gas distributor

- flame stability disk

- Adjustable air pressure switch, with graduated selector, to guarantee burner lock out in the case

of insufficient combustible air

- Protection filter against radio interference

- IP 40 electric protection level.

3. The Fan

Forced air circulation with booth walls and floor,curing a very good temperature uniformity result

4. The PLC type controll sytem of the powder curing oven

Control provides high precision heating process, it offers all the features you need. The LED display allows

you to set the temperature,as well as the duration of heating process at the desired temperature.

About us:

Installation in customer's factory

We have many years experiences on powder coating. We are a typical Chinese supplier and specialized in the research, development and production of powder spray booths, powder coating oven,powder coating gun,powder coating line. We insist in offering superior quality products and efficient service.

If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us. We are looking forward to forming successful business relationships with new clients around the world in the near future.