thermosetting powder coating

Item specifics

- Main Raw Material

- Polyurethane

- Usage

- Appliance Paint

- Application Method

- Spray

- State

- Powder Coating

- powder coating

- polyester

Review

Description

thermosetting powder coatingpolyester powder coating/electrostatic powder coating

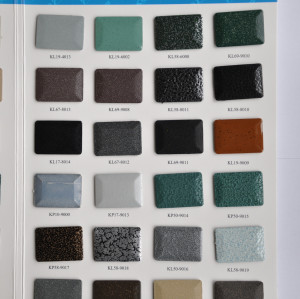

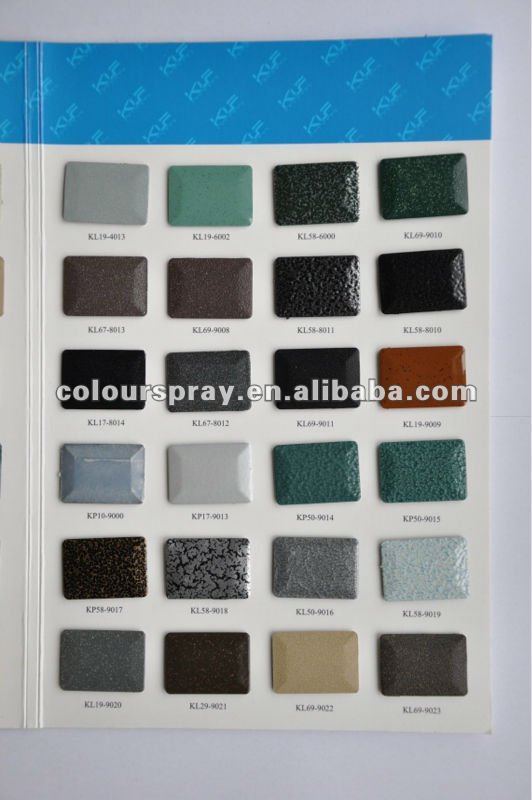

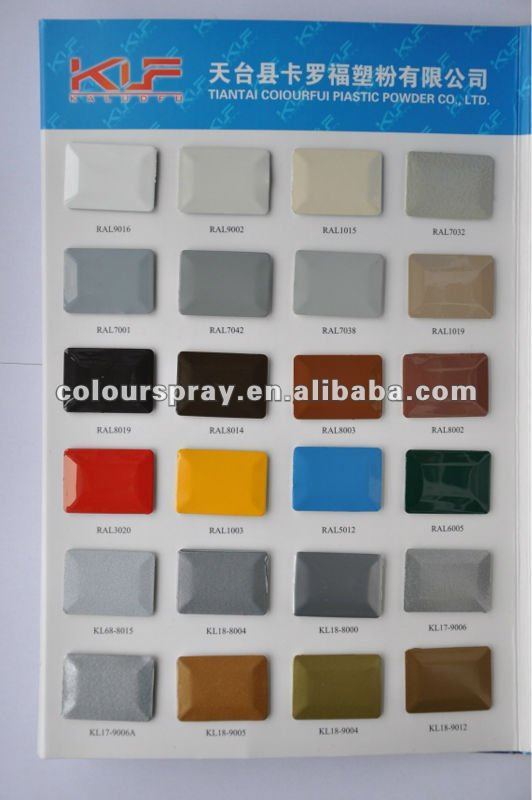

Product variety:

1. Full gloss

2. Dead lustre or less lustre

3. Ripple mark, mallear atria, cockel and other special effect of lacework

4. Lucency and translucency

5. Multicolor

6. Fluorescene

7. Metal powder effect

Curing condition: Product variety: 200C/10minutes, or customized

Powder coating is a type of coating that is applied as a free-flowing, dry powder. The main difference between a conventional liquid paint and a powder coating is that the powder coating does not require a solvent to keep the binder and filler parts in a liquid suspension form. The coating is typically applied electrostatically and is then cured under heat to allow it to flow and form a "skin". The powder may be a thermoplastic or a thermosetpolymer. It is usually used to create a hard finish that is tougher than conventional paint. Powder coating is mainly used for coating of metals, such as "whiteware," aluminium extrusions, and automobile and bicycle parts. Newer technologies allow other materials, such as MDF (medium-density fibreboard), to be powder coated using different methods.