Manual Powder Coating spray paiting Booth

- Price

- US $1-2000

- Model

- COLO-S-2315

- MOQ

- 1 piece

Item specifics

- Condition

- New

- Type

- Powder Coating Booth

- Substrate

- Iron

- Coating

- Powder Coating

- Voltage

- 380-415V

- Power(W)

- 3.6KW

- Dimension(L*W*H)

- 2300*1500*1500mm

- Weight

- 600kgs

- Certification

- CE

- Warranty

- 1YEAR

- After-sales Service Provided

- Overseas service center available

- cabina

- powder coating

Review

Description

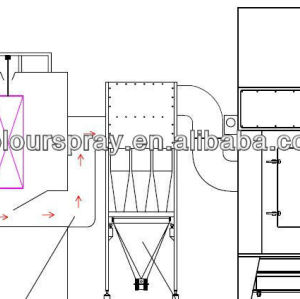

Economical Powder Coating Booth Quick reliable powder changes With recovery system Cartridge filter Single operator

Technical date

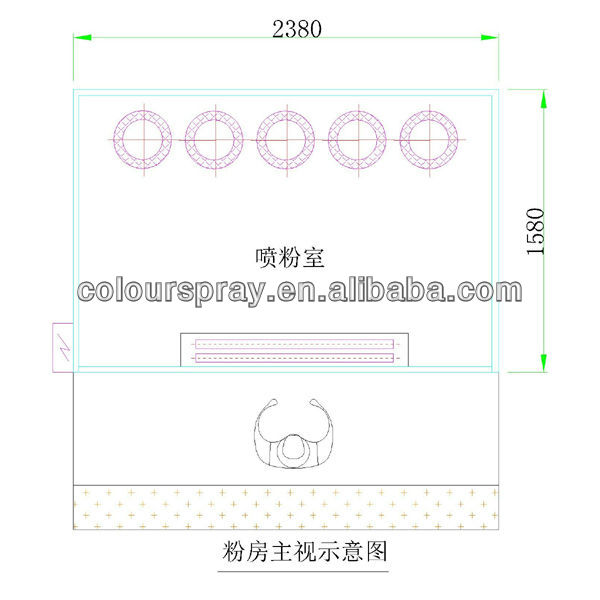

| Booth Model: | COLO-S-2315 |

| Worksize dimensions | 2300 width x 1500 height x 1500 depth |

| Overall dimensions | 2550 width x 2240 height x 1500 depth |

| Power supply | Electric |

| Nominal power | 4kW |

| Voltage | 380V-415V |

| Frequency | 50-60Hz |

| Filters | Polyester |

| Filters No | 4 |

| Filters hang type | Easy to change type, easy on/off |

| Filter area | 11m2 |

| Filter cleaning system | Jet Venturi |

| Ventilator type | Aluminium ray rotor 4pc |

| Exhaust air | Nominal 5200m3/h |

| Doors | one door |

| Warranty | 12 months |

Filter

325mm*900mm

325mm*660mm

325mm*660mm

drawing

Smaller Spray booth

include fans, motors, nut and bolt fasteners, filters, detailed drawings and instructions, all included in one single shipment.

powder spray booth is an economical solution for basic powder coating operations requiring reclaim capability in continuous production situations.

For job shops, first-time powder coaters and to suppliment large in-house powder coating operations,this powder spray booths offer a variety of configuration options.

Booths size could Custom designed,Manual and automatic spray stations are also available.

Other features include:

Durable, long-life powder-coated steel structure with high-quality galvanized canopy and floor

Low-profile booth base eliminates operator platforms

Requires only quick, easy conncet electrical and pneumatics to start production .

During operation overspray powder accumulates on the cartridge filters. As the cartridge filters load, airflow decreases and the negative pressure rises within the air handler. A timer activates a system of air purging valves that clear the cartridge filters of the accumulated powder to ensure maximum flitter life.

Othe equipment such as the manual spray gun and oven could order together.

manual spray gun COLO-800V

powder curing oven

Powder coating System

The spray booth is manufacture according to your requirements.

All powder coating booths are formed on CNC equipment

Not to be used for wet painting

If you are an expanding manufacturer or new business,we can provide the necessary assistance in planning your process.

More information,please feel free to contact us by the way as follow:

Welcome guests from all countries in the world visit our factory , choosing colo it is choosing quality machine, , high-quality after-sales service.holesale, sales and service of electrostatic coating. Its products have continuously been developed and improved day by day ...