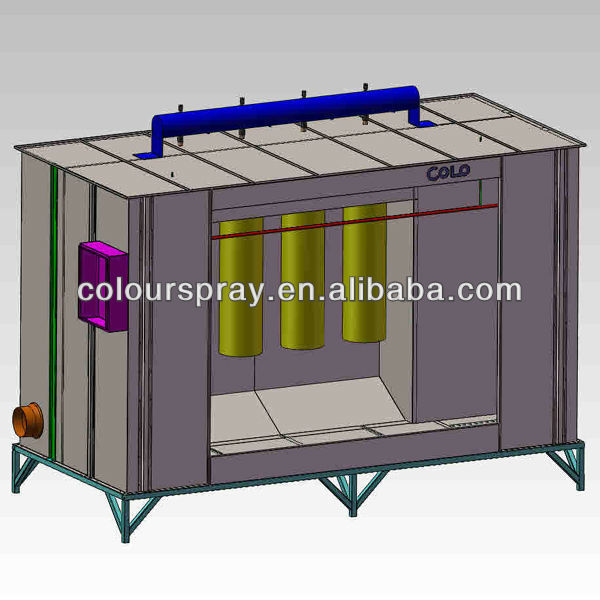

electrostatic paint coating booth

- Price

- US $0-20000

- Model

- COLO-S-2(3.5*1.5*2.1)

- MOQ

- 1 piece

Item specifics

- Condition

- New

- Type

- Coating Production Line

- Substrate

- Steel

- Coating

- Powder Coating

- Voltage

- 380V/110V/220V

- Power(W)

- 5.5kw

- Dimension(L*W*H)

- 3.5*1.5*2.1m

- Weight

- 300kgs

- Certification

- CE

- Warranty

- 1 Year

- After-sales Service Provided

- Overseas third-party support available

- coating machine

- powder spray machine

Review

Description

1, electrostatic paint coating booth ,powder coating booth ,For metallic workpiece powder coating

COLO is a manufacturer of advanced powder coating booths

for superior powder transfer efficiency, operator safety and comfort, and Quick color change

Cartridge filter and Cyclone style powder coating booths

Our powder coating booth designs are simple, yet technologically advanced to meet the demanding challenges of:

- Operator Safety

- Environmental compliance

- Production capacity and operational efficiency

- Color changeover

- Air management - for safety, quality and efficiency

- Maintenance

Benefits of our Powder Booths

longer lasting, more durable, quieter

The powder booth is one of the most critical components of the product finishing process

For COLO-S-02 (3.5*1.5*2) ,The description as follow:

L3500×W1500×H2100

Body material δ=1.2mm cold plate, fold. with a powder hopper

Fliter number 2pcs/set Flither

sizeφ325×900 fast-loading

Recycling fan1/set 4-72-2.8A 5.5KW

DATA:

Model | COLO-S-02(3.5*1.5*2.1M) |

| Booth Type | Closed |

| Worksize dimensions | 1200width x 1300 height x 800 depth |

| Overall dimensions | 3500width x 2100 height x 1500 depth |

| Weight | 460kg |

| Power supply | Electric |

| Nominal power | 0,69kW |

| Voltage | 380V |

| Frequency | 50-60Hz |

| Filters | Polyester |

| Filters count | 3 |

| Filters hang type | easy for change |

| Filter cleaning system | Pneumatic - Jet Venturi |

| Air consumption | 5100m3/h |

| Warranty | 12 months |

Electrostatic powder spraying booth

1,Full automatic control

2,Small area occupation

3,Low energy consumption

4,size is customize

5,Pulse valves and solenoids

6,Primary filter module: cartridge type

include fans, motors, nut and bolt fasteners, filters, detailed drawings and instructions, all included in one single shipment.

powder spray booth is an economical solution for basic powder coating operations requiring reclaim capability in continuous production situations.

For job shops, first-time powder coaters and to suppliment large in-house powder coating operations,this powder spray booths offer a variety of configuration options.

Booths size could Custom designed,Manual and automatic spray stations are also available. Other features include:

Durable, long-life powder-coated steel structure with high-quality galvanized canopy and floor

Low-profile booth base eliminates operator platforms

Requires only quick, easy conncet electrical and pneumatics to start production .

Fan motor is 1.5KW-5.5KW.

During operation overspray powder accumulates on the cartridge filters. As the cartridge filters load, airflow decreases and the negative pressure rises within the air handler. A timer activates a system of air purging valves that clear the cartridge filters of the accumulated powder to ensure maximum flitter life.

COLO are specialized in complete electrostatic powder coating line, paint coating plants ,curing and drying ovens, cartridge type and cyclone recovery systems, spray booth, conveyor systems, Also we are supplier of powder coating, powder filters, powder coating machine,powder coating equipment,powder coatting gun,,Reciprocator, painting guns, pumps and their equipments.