automatic powder coating line Cyclone system

- Model

- COLO-S

Item specifics

- Condition

- New

- Type

- Coating Production Line

- Substrate

- Iron

- Coating

- Powder Coating

- Voltage

- As required

- Power(W)

- As required

- Dimension(L*W*H)

- As required

- Weight

- As required

- Certification

- CE

- Warranty

- 1 year

- After-sales Service Provided

- Engineers available to service machinery overseas

- MOQ

- 1 piece

- Guarantee

- 1 year

- product

- Cyclone devices

- machine

- powder coating equipment

- line

- powder coating line

- system

- powder coating system

- Features

- automatic

- use for

- powder spraybooth

Review

Description

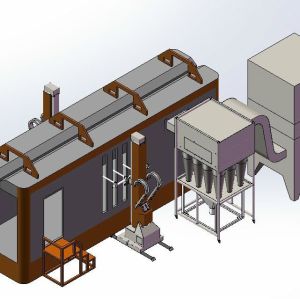

1,automatic powder coating line Cyclone devices

2,Full automatic control

3,Small area occupation

4,High productivity

Advantage of multi-cyclone powder recovery system are: the separation of its multi-level and set the structure on to ensure rapid and thorough separation of the mixture into the future. Its unique multi-cyclone tube and filter elements made of special materials to ensure high separation efficiency, good effect. Each segment separated from each other but complement each other, especially in the key is cyclone tube, filter, cleaning pulse gas system coordination, both to ensure the recovery and separation of high quality, while ensuring the normal spray chamber work. Promotion and popularization of the system will greatly improve the powder recovery efficiency, improve the quality of spraying and improve the environment.

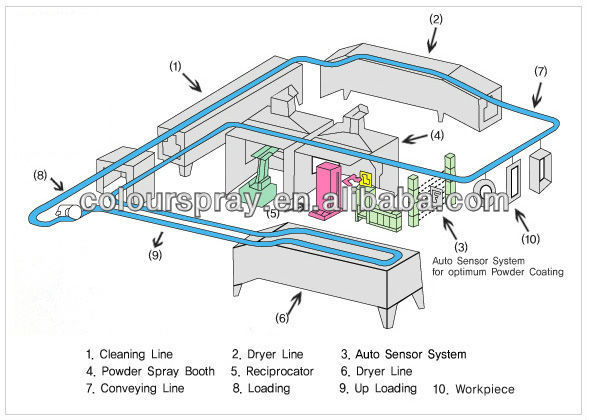

automatic powder paint booth ,is one of the parts of Electrostatic automatic powder coating plant ,this consists of pretreatment, powder coating booth,

drying oven and curing oven, conveyor system and electric control system.as the below picture show

We offer fully automatic SCADA controlled powder coating plants with quick colour change technology.It consists of automatic powder coating booth with reciprocator and iautomatic powder coating gun,powder recycling unit,powder supplying hopper, electrical/diesel/LPG fired camel bake oven,monorial conveyor unit and control panel.

We have specialized engineers to design and manufacture automatic plants with various processes as per customers requirement.This plant consists of several processes which are made into one by our specialized design.

a single continuous powder coating process, whereby items are attached to an automated track, which subsequently travels through four separate powder coating process stages. This process delivers a pre-treated and finished powder coated component at the end of the track.

COLO Powder Coating Systems is a top supplier of powder coating systems and powder coating equipment including automated equipment, spray booths and spare parts famous brand in china.